Factory making Mechanical Fine Screen - Good Quality Solid-Liquid Separator Rotary Drum Filter Screen – Holly Detail:

Product Description

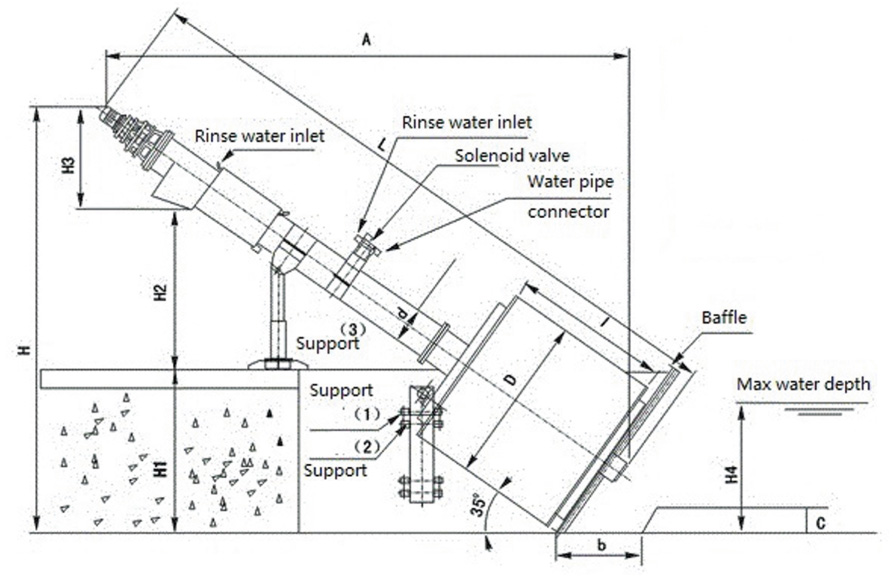

The Rotary Drum Screen is a reliable and well-proven inlet screen for municipal sewage treatment plants,industrial wastewater and process water screening.Its operation is baesd upon a unique system that also allows a combination of screening, washing, transport, compaction and dewatering in a single unit.The screening elements can be either wedge wire spaced at 0.5-6mm, or 1-6mm perforated drums.Depending on the aperture size selected and the screen diameter(screen basket diameter of up to 3000 mm are available), the throughput can be individually adjusted to specific site requirements.The Rotary Drum Screen is completely made of stainless steel and can be installed either directly in the channel or in a separate tank.

Product Features

1.The uniformity of water-distribution increases the treating capacity.

2.The machine is driven by chain transmission, of high efficiency.

3.It is equipped with reverse flushing device to prevent the screen clogging.

4.Double overflow plate to prevent wastewater splash .

Typical Applications

This is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment. It is mainly used in municipal sewage treatment plants, residential quarters sewage pretreatment devices, municipal sewage pumping stations, waterworks and power plants, also it can widely be applied to water treatment projects of various industries, such as textile, printing and dyeing, food, fishery, paper, wine, butchery, curriery etc.

Technical Parameters

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | ||

| Drum Diameter(mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | ||

| Drum Length I(mm) | 500 | 620 | 700 | 800 | 1000 | 1150 | 1250 | 1350 | ||

| Transport Tube d(mm) | 219 | 273 | 273 | 300 | 300 | 360 | 360 | 500 | ||

| Channel Width b(mm) | 650 | 850 | 1050 | 1250 | 1450 | 1650 | 1850 | 2070 | ||

| Max Water Depth H4(mm) | 350 | 450 | 540 | 620 | 750 | 860 | 960 | 1050 | ||

| Installation Angle | 35° | |||||||||

| Channel Depth H1(mm) | 600-3000 | |||||||||

| Discharge Height H2(mm) | Customized | |||||||||

| H3(mm) | Confirmed by the type of reducer | |||||||||

| Installation Length A(mm) | A=H×1.43-0.48D | |||||||||

| Total Length L(mm) | L=H×1.743-0.75D | |||||||||

| Flow rate (m/s) | 1.0 | |||||||||

| Volume(m³/h) | Mesh(mm) | 0.5 | 80 | 135 | 235 | 315 | 450 | 585 | 745 | 920 |

| 1 | 125 | 215 | 370 | 505 | 720 | 950 | 1205 | 1495 | ||

| 2 | 190 | 330 | 555 | 765 | 1095 | 1440 | 1830 | 2260 | ||

| 3 | 230 | 400 | 680 | 935 | 1340 | 1760 | 2235 | 2755 | ||

| 4 | 235 | 430 | 720 | 1010 | 1440 | 2050 | 2700 | 3340 | ||

| 5 | 250 | 465 | 795 | 1105 | 1575 | 2200 | 2935 | 3600 | ||

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for Factory making Mechanical Fine Screen - Good Quality Solid-Liquid Separator Rotary Drum Filter Screen – Holly, The product will supply to all over the world, such as: Afghanistan, Albania, Finland, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

Best quality Pond Aerator Diffuser - QJB Type ...

-

New Delivery for Submersible Jet Mixer - QJB T...

-

OEM/ODM Manufacturer Double Screw Press - QJB ...

-

Online Exporter Slurry Filter Press - QJB Type...

-

Good Wholesale Vendors Dewatering Screw - QJB ...

-

Professional China Screw Press Sludge Dewaterin...