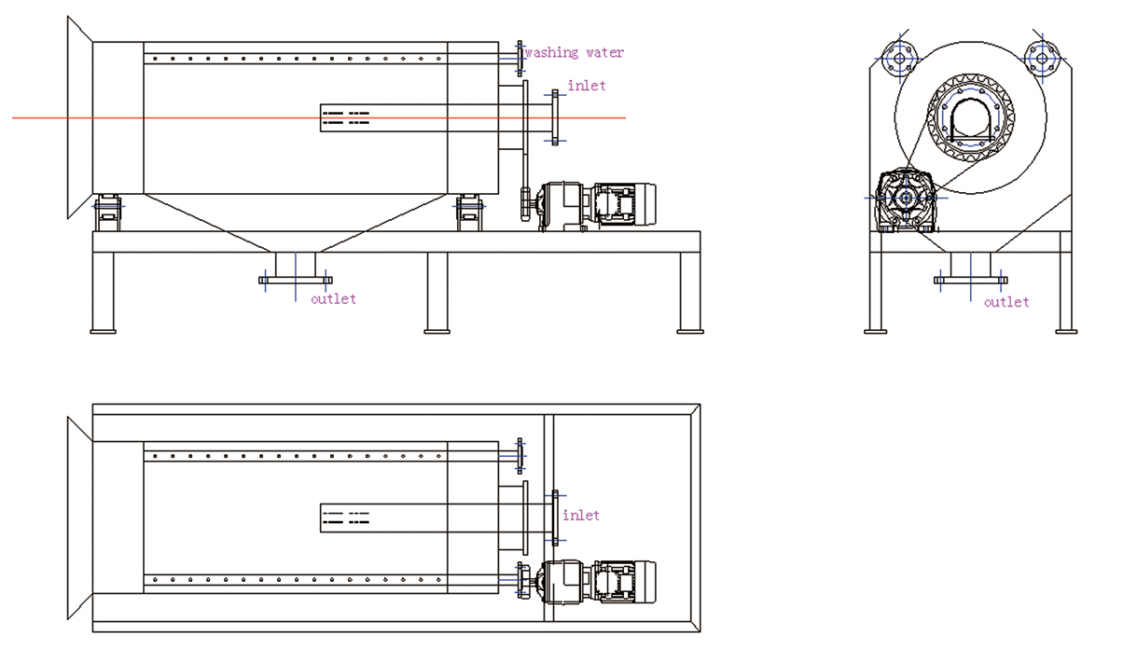

Factory making Mechanical Fine Screen - Mechanical Internal Feed Rotary Drum Filter Screen – Holly Detail:

Product Features

1.The material is high-strength and corrosion-resistant stainless steel; Less used field area; Convenient construction; It can be directly fixed with expansion bolts without channel construction; Inlet and outlet water can be connected with pipes.

2.The screen will not be blocked by waste solid because the machine is inverted trapezoid cross section

3.The machine is controlled by adjustable-speed motor, which can maintain optimum working condition according to water flow.

4.Special washing device can brush away the impurities on the surface of screen, after twice internal brush, it will achieve the best cleaning effect.

Typical Applications

This is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment. It is mainly used in municipal sewage treatment plants, residential quarters sewage pretreatment devices, municipal sewage pumping stations, waterworks and power plants, also it can widely be applied to water treatment projects of various industries, such as textile, printing and dyeing, food, fishery, paper, wine, butchery, curriery etc.

Technical Parameters

| Model | Screen Size | Dimensions | Power | Material | Removal rate | |

| Solid size | Solid size | |||||

| HlWLN-300 | φ300*800mm Space:0.15-5mm |

1500*500*1200mm | 0.55KW | SS304 | 0.95 | 0.55 |

| HlWLN-400 | φ400*1000mm Space:0.15-5mm |

1800*600*1300mm | 0.55KW | SS304 | 0.95 | 0.55 |

| HlWLN-500 | φ500*1000mm Space:0.15-5mm |

1800*700*1300mm | 0.75KW | SS304 | 0.95 | 0.55 |

| HlWLN-600 | φ600*1200mm Space:0.15-5mm |

2400*700*1400mm | 0.75KW | SS304 | 0.95 | 0.55 |

| HlWLN-700 | φ700*1500mm Space:0.15-5mm |

2700*900*1500mm | 0.75KW | SS304 | 0.95 | 0.55 |

| HlWLN-800 | φ800*1600mm Space:0.15-5mm |

2800*1000*1500mm | 1.1KW | SS304 | 0.95 | 0.55 |

| HlWLN-900 | φ900*1800mm Space:0.15-5mm |

3000*1100*1600mm | 1.5KW | SS304 | 0.95 | 0.55 |

| HlWLN-1000 | φ1000*2000mm Space:0.15-5mm |

3200*1200*1600mm | 1.5KW | SS304 | 0.95 | 0.55 |

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Factory making Mechanical Fine Screen - Mechanical Internal Feed Rotary Drum Filter Screen – Holly, The product will supply to all over the world, such as: Juventus, Jamaica, Hungary, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Discount wholesale K1 Filter Media - PP and PV...

-

Factory supplied K1 Media Alternative - QJB Ty...

-

8 Year Exporter Volute Sludge Dewatering Machin...

-

Ordinary Discount Rake Bar Screen - QJB Type S...

-

OEM/ODM Supplier Screening Filter - QJB Type S...

-

Hot New Products Daf System Dissolved Air Flota...