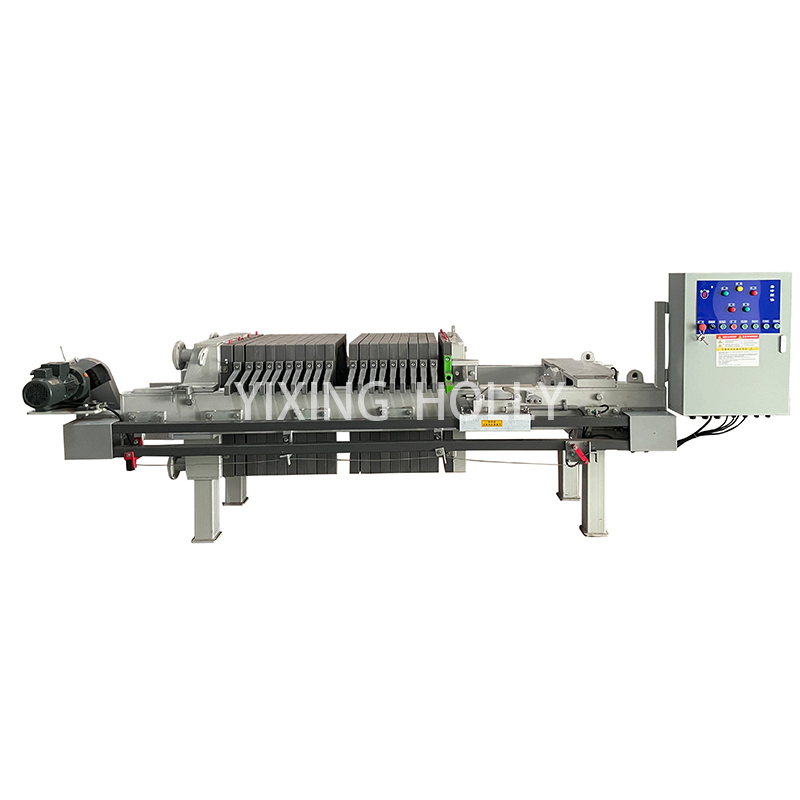

Low price for Belt Press For Sludge Dewatering - High Efficiecnt Sludge Dewatering Recessed Plate Filter Press – Holly Detail:

Product Description

Filter presses separate suspended solids from liquids.What are the Four Main Components of a Filter Press? 1.Frame2.Filter Plates3.Manifold (piping and valves)4.Filter Cloth (This is key for optimizing filter press operations.

Filter presses result in the driest cake with the cleanest filtrate when compared to other dewatering equipment for a respective application. Proper selection of cloths, plates, pumps and ancillary equipment/process, such as precoat, cake wash and cake squeeze is critical to optimal operation of the dewatering system.Holly Filter Press is divided into Fast open filter press, High pressure filter press, Frame filter press, Membrane filter press with there are also dozens of filtering cloth types such as multifilament polypropylene filter cloth, polypropylene Mono/ multifilament filter cloth, polypropylene Monofilament filter cloth and Fancy twill weave filter cloth.

Working Principle

During the fill cycle, the slurry pumps into the filter press and distributes evenly during the fill cycle. Solids build up on the filter cloth, forming the filter cake in the void volume of the plate. The filtrate, or clean water, exits the filter plates through the ports and discharges clean water out the side of the plates.

Filter presses are a pressure filtration method. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of solids. This forms the cake. The filter cakes release when the plates are full, and the cycle is complete.

Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Applications

printing and dyeing sludge, electroplating sludge, papermaking sludge, chemical sludge, municipal sewage sludge, mining sludge, heavy metal sludge, leather sludge, drilling sludge, brewing sludge, food sludge

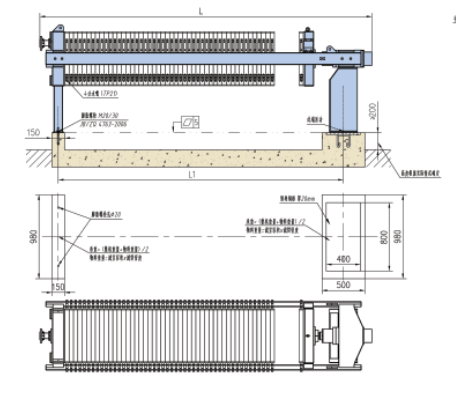

Technical Parameters

| Model | Filter Area(²) | Filter Chamber Volume(L) | Capacity(t/h) | Weight(kg) | Dimension(mm) |

| HL50 | 50 | 748 | 1-1.5 | 3456 | 4110*1400*1230 |

| HL80 | 80 | 1210 | 1-2 | 5082 | 5120*1500*1400 |

| HL100 | 100 | 1475 | 2-4 | 6628 | 5020*1800*1600 |

| HL150 | 150 | 2063 | 3-5 | 10455 | 5990*1800*1600 |

| HL200 | 200 | 2896 | 4-5 | 13504 | 7360*1800*1600 |

| HL250 | 250 | 3650 | 6-8 | 16227 | 8600*1800*1600 |

Packing

Product detail pictures:

Related Product Guide:

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of Low price for Belt Press For Sludge Dewatering - High Efficiecnt Sludge Dewatering Recessed Plate Filter Press – Holly, The product will supply to all over the world, such as: Grenada, European, Orlando, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!