Product Features

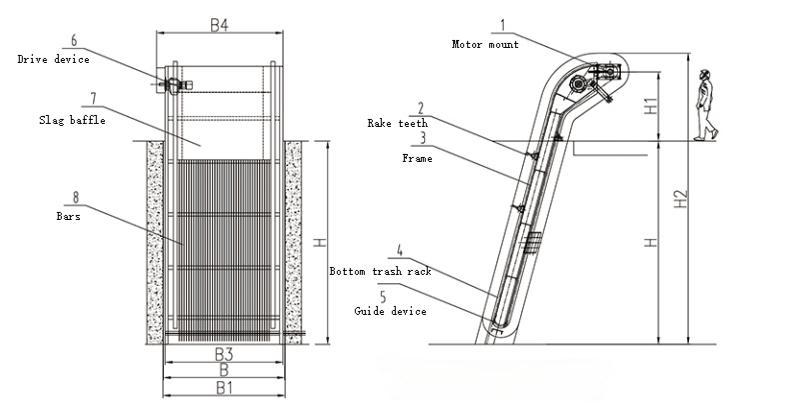

1. The drive device is directly driven by a cycloidal pinwheel or helical gear motor, with low noise, tight structure, and smooth operation;

2. The rake teeth are bevel-tipped and welded to the horizontal axis as a whole, which can pick up larger garbage and debris;

3. The frame is an integral frame structure with strong rigidity, easy installation, and less daily maintenance;

4. The equipment is easy to operate and can be directly controlled on-site/remotely;

5. To prevent accidental overload, mechanical shear pins and overcurrent dual protection are provided to ensure safe and reliable operation of the equipment;

6. A secondary grille is set at the bottom. When the tooth rake moves from the back of the main grille to the front side, the secondary grille automatically fits with the main grille to prevent the short circuit of the water flow and the flow of suspended debris.

Technical Parameters

|

Model |

HLBF-1250 |

HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 |

|

Machine width B(mm) |

1250 |

2500 |

3500 |

4000 |

4500 |

5000 |

|

Channel width B1(mm) |

B1=B+100 |

|||||

|

Mesh size b(mm) |

20~150 |

|||||

|

Installation angle |

70~80° |

|||||

|

Channel depth H(mm) |

2000~6000 (According to customer ‘s requirement.) |

|||||

|

Discharge height H1(mm) |

1000~1500 (According to customer ‘s requirement.) |

|||||

|

Running speed(m/Min) |

Around 3 |

|||||

|

Motor power N(kW) |

1.1~2.2 |

2.2~3.0 |

3.0~4.0 |

|||

|

Civil engineering demand load P1(KN) |

20 |

35 |

||||

|

Civil engineering demand load P2(KN) |

20 |

35 |

||||

|

Civil engineering demand load △P(KN) |

2.0 |

3.0 |

||||

Note: P1(P2) is calculated by H=5.0m,for every 1m H increased,then P total=P1(P2)+△P

Dimensions

Water Flow Rate

|

Model |

HLBF-1250 |

HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 | ||

|

Water depth before screen H3 (mm) |

3.0 |

|||||||

|

Flow rate (m/s) |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

||

|

Mesh size b (mm) |

40 |

Flow rate (l/s) |

2.53 |

5.66 |

8.06 |

9.26 |

10.46 |

11.66 |

|

50 |

2.63 |

5.88 |

8.40 |

9.60 |

10.86 |

12.09 |

||

|

60 |

2.68 |

6.00 |

8.64 |

9.93 |

11.22 |

12.51 |

||

|

70 |

2.78 |

6.24 |

8.80 |

10.14 |

11.46 |

12.75 |

||

|

80 |

2.81 |

6.30 |

8.97 |

10.29 |

11.64 |

12.96 |

||

|

90 |

2.85 |

6.36 |

9.06 |

10.41 |

11.70 |

13.11 |

||

|

100 |

2.88 |

6.45 |

9.15 |

10.53 |

11.88 |

13.26 |

||

|

110 |

2.90 |

6.48 |

9.24 |

10.62 |

12.00 |

13.35 |

||

|

120 |

2.92 |

6.54 |

9.30 |

10.68 |

12.06 |

13.47 |

||

|

130 |

2.94 |

6.57 |

9.36 |

10.74 |

12.15 |

13.53 |

||

|

140 |

2.95 |

6.60 |

9.39 |

10.80 |

12.21 |

13.59 |

||

|

150 |

2.96 |

6.63 |

9.45 |

10.86 |

12.27 |

13.65 |

||