We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Special Design for China Continuous Belt Filter Press in Wastewater Treatment Biological, Customer fulfillment is our main intention. We welcome you to set up organization relation with us. For further more info, please do not hesitate to speak to with us.

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for China Wastewater Treatment, Papermaking Wastewater, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one’s detailed specifications.

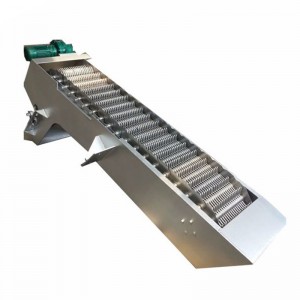

Product Features

1. Material of the main structure : SUS304/316

2. Belt : Has a long service life

3. Low power consumption, slow-speed of revolution and low noise

4. Adjustment of belt: Pneumatic regulated, ensures the stability of the machine

5. Multi-point safety detection and emergency stop device:improve the operation.

6. The design of the system is obviously humanized and provides convenience in operation and maintenance.

Applications

The Sludge Dewatering Screw Press can be widely used for various wastewater treatment systems such as municipal, petrochemical, chemical fiber, paper making, pharmaceutical, leather and other industrial water treatment system. Also it can be used for Dairy Farm Manure Treatment, Palm Oil Sludge, Septic Sludge, etc. The practical operation shows that Dewatering Screw Press can bring considerable economic and social benefits for users.

Technical Parameters

| Model Item | DNY 500 |

DNY 1000A |

DNY 1500A | DNY 1500B | DNY 2000A | DNY 2000B | DNY 2500A | DNY 2500B | DNY 3000 |

| Output Moisture Content% | 70-80 | ||||||||

| Polymer Dosing Rate% | 1.8-2.4 | ||||||||

| Dried Sludge Capacity kg/h’ | 100-120 | 200-203 | 300-360 | 400-460 | 470-550 | 600-700 | |||

| Belt Speed m/min | 1.57-5.51 | 1.04-4.5 | |||||||

| Main Motor Power kW | 0.75 | 1.1 | 1.5 | ||||||

| Mixing Motor Power kW | 0.25 | 0.25 | 0.37 | 0.55 | |||||

| Effective Belt Width mm | 500 | 1000 | 1500 | 2000 | 2500 | 3000 | |||

| Water Consumption m3/h | 6.2 | 11.2 | 16 | 17.6 | 20.8 | 22.4 | 24.1 | 25.2 | 28.8 |

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Special Design for China Continuous Belt Filter Press in Wastewater Treatment Biological, Customer fulfillment is our main intention. We welcome you to set up organization relation with us. For further more info, please do not hesitate to speak to with us.

Special Design for China Wastewater Treatment, Papermaking Wastewater, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one’s detailed specifications.

-

Hot-selling Aquaculture Drum Filter and Drum Fi...

-

Factory Selling Centrifugal Type Submersible Ae...

-

Supply OEM Aquaculture Protein Skimmer for Fish...

-

High Quality Conventional Wastewater Treatment ...

-

Cheap PriceList for High Quality Fish Farming A...

-

IOS Certificate Aquaculture Drum Filter and Dru...