Product Description

This device is generally applied before the primary clarifier of the city sewage treatment plant. After the sewage going through the grille, the device is used to separate those large inorganic particles in the sewage (diameter greater than 0.5mm). Most of the sewage is separated by air lifting, if the sewage is separated by pump lifting, it will have higher requirements for anti-wearing. The steel pooling body is suitable for the use of small and medium flow. It applies to single cyclone sand grit chamber; the combined structure function is similar to that of Dole sand grit chamber. But in the same situation, this combined structure occupies less area and has higher efficiency.

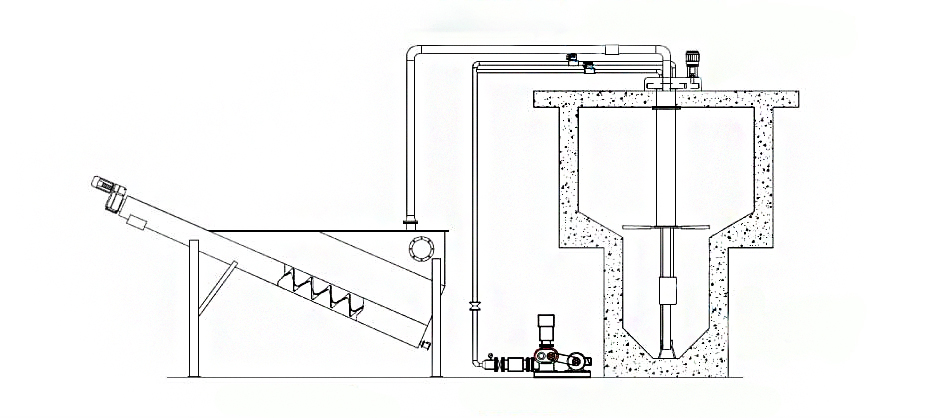

Working Principle

The raw water enters from the tangential direction, and form the cyclone initially. By the support of the impeller, these cyclones will have certain speed and fluidization which will have sands with organic compounds washed mutually, and sink to the hopper center by gravity and swirl resistance. Stripped organic compounds will flow up direction with the axial. Sand accumulated by the hopper lifted by air or pump will be completely separated in the separator, then the separated sand will be drained to the dustbin (cylinder) and the sewage will be back to the bar screen wells.

Product Features

1. Less area occupation, compact structure. Little influence on the surrounding environment and good environmental conditions.

2. The sanding effect will not change too much due to the flow and the sand-water separation is good. The water content of the separated sand is low, so it is easy to transport.

3. The device adopts PLC system to control the sand washing period and sand discharging period automatically, which is simple and reliable.

Technical parameters

| Model | Capacity | Device | Pool Diameter | Extraction Amount | Blower | ||

| Impeller speed | Power | Volume | Power | ||||

| XLCS-180 | 180 | 12-20r/min | 1.1kw | 1830 | 1-1.2 | 1.43 | 1.5 |

| XLCS-360 | 360 | 2130 | 1.2-1.8 | 1.79 | 2.2 | ||

| XLCS-720 | 720 | 2430 | 1.8-3 | 1.75 | |||

| XLCS-1080 | 1080 | 3050 | 3.0-5.0 | ||||

| XLCS-1980 | 1980 | 1.5kw | 3650 | 5-9.8 | 2.03 | 3 | |

| XLCS-3170 | 3170 | 4870 | 9.8-15 | 1.98 | 4 | ||

| XLCS-4750 | 4750 | 5480 | 15-22 | ||||

| XLCS-6300 | 6300 | 5800 | 22-28 | 2.01 | |||

| XLCS-7200 | 7200 | 6100 | 28-30 | ||||

Appliction

Textile Sewage

Industrial Sewage

Domestic Sewage

Catering Sewage

Municipal