Product Description

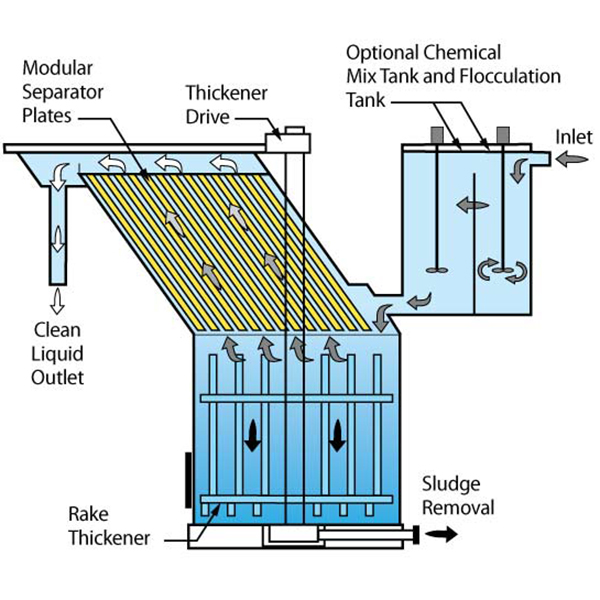

Lamella clarifier inclined plate settler (IPS) is a type of settler designed to remove particulates from liquids.

They often employed in primary water treatment in place of conventional settling tanks. The inclined tube and inclined plate precipitation water purification method is formed by placing the sludge suspension layer above the inclined tube inclined plate with an inclination angle of 60 degrees, so that the suspended matter in the raw water accumulates on the bottom surface of the inclined tube. After that, a thin mud layer is formed, which slides back to the mud slag suspension layer after relying on the action of gravity, and then sinks into the mud collecting bucket, and then is discharged into the sludge pool by the mud discharge pipe for treatment or comprehensive utilization. The clean water above will gradually rise to the water collection pipe for discharge, which can be directly discharged or reused.

Product Usage

The lamella clarifier can be used as a supporting system equipment for water treatment processes such as air flotation and elevating methods, and can treat the following kinds of sewage.

1. The removal rate of waste water, copper, iron, zinc and nickel containing a variety of metal products in the electric water can be over 93%, and the discharge standard can be reached after treatment in the inclined tube inclined plate sedimentation tank.

2. The turbidity of coal mines and wastewater can be increased from 600-1600 mg/liter to 5 mg/liter.

3. The chromaticity removal rate of printing and dyeing, bleaching and dyeing and other industrial wastewater is 70-90%, and the COD removal rate is 50-70%.

4. The removal rate of COD can reach 60-80% in wastewater from leather, food and other industries, and the removal rate of impurity solids is more than 95%.

5. The COD removal rate of chemical wastewater is 60-70%, the chromaticity removal rate is 60-90%, and the suspended solids can meet the discharge standard.

Product Advantages

1. Simple structure, no wearing parts, durable and less maintenance

2. Easy to operate and maintain

3. Continuous operation

4. No moving parts

5. Standard flange connections

6. Low power consumption

7. Occupy smaller area, less investment and high efficiency

Application

Fly Ash Waste/Flue Gas Desulfurization (FGD) Waste/Clarification

Solids Recovery/Cooling Tower Blowdown/Iron Removal

Municipal Water Treatment/Semiconductor Process Waste

Whitewater (Pulp & Paper)/Groundwater Remediation

Potable Water Clarification/Landfill Leachate

Boiler Waste Treatment/Heavy Metals Removal

Filter Press Belt Wash/Battery Plant Heavy Metals Removal

Hazardous Waste Remediation/Brine Clarification

Plating and Finishing Wastes/Food & Beverage Waste

Trace Metals Reduction/Storm Water Management

Bleach Plant Wash Water/Incinerator Wet Scrubber

Potable Water Pretreatment

Packing

Specifications

| Model | Capacity | Material | Dimensions(mm) |

| HLLC-1 | 1m3/h | Carbon Steel(Expoxy Painted) or Carbon Steel(Expoxy Painted)+FRP Lining |

Φ1000*2800 |

| HLLC-2 | 2m3/h | Φ1000*2800 | |

| HLLC-3 | 3m3/h | Φ1500*3500 | |

| HLLC-5 | 5m3/h | Φ1800*3500 | |

| HLLC-10 | 10m3/h | Φ2150*3500 | |

| HLLC-20 | 20m3/h | 2000*2000*4500 | |

| HLLC-30 | 30m3/h | 3500*3000*4500 Sedimentation area: 3.0*2.5*4.5m |

|

| HLLC-40 | 40m3/h | 5000*3000*4500 Sedimentation area:4.0*2.5*4.5m |

|

| HLLC-50 | 50m3/h | 6000*3200*4500 Sedimentation area:4.0*2.5*4.5m |

|

| HLLC-120 | 120m3/h | 9500*3000*4500 Sedimentation area:8.0*3*3.5 |